Turbine Installation Methodology

For details of the code implementation, please see Turbine Installation API.

Overview

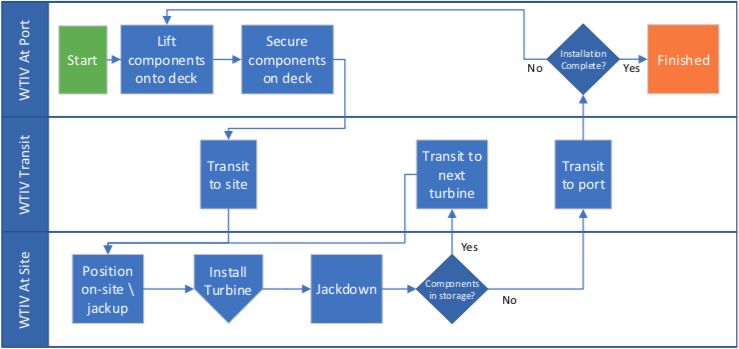

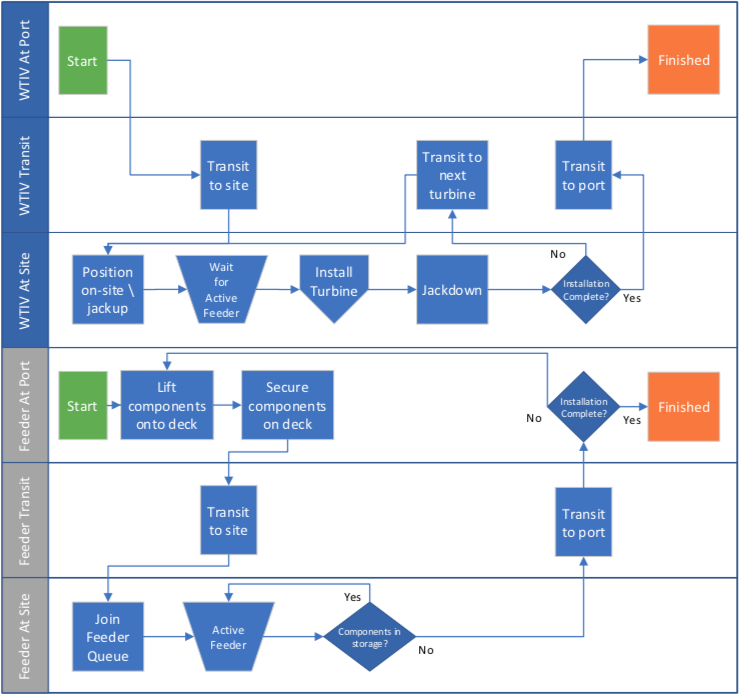

The TurbineInstallation module simulates the installation of turbines at

site. For the purpose of this module, the turbine is discretized into five

different components: a tower, nacelle and three turbine blades. The module can

be configured such that a single wind turbine installation vessel (WTIV)

transports and installs all of the turbine components or it can be configured

to include feeder barges that transport the components to site.

Process Diagrams detailing the vessel logistics for these two installation

can be seen below.

Note

For both installation strategies the WTIV performs all of the on site operations with its onboard crane, either picking components from its own deck or a neighboring feeder barge.

Configuration

To configure TurbineInstallation to utilize feeder barges to transit the

turbine components from port, add the following configuration to the project

configuration.

config = {

...

"feeder": "example_feeder", # name of vessel configuration file without extension

"num_feeders": 2,

...

}

Processes

Port Operations

Vessels load items and fasten them on their deck at port using the port crane. Ports are configured with one crane by default, which limits multiple vessels from accessing port resources at a time. This can be overridden by configuring a port with additional cranes in a project configuration:

"port": {

"num_cranes": 2 # Two vessels can access port resource simultaneously.

}

The default times for fastening each component to deck are listed below.

Component |

Inputs |

Default |

|---|---|---|

Tower |

|

4h |

Nacelle |

|

4h |

Blade |

|

1.5h |

Currently, all vessels are only able to load multiples of complete sets of components (tower, nacelle and three blades).

Site Preperation

Once the WTIV and a set of components are at site (either on the WTIV or a feeder barge), the WTIV positions itself onsite and jacks up. The following table outlines the inputs and default times for these tasks.

Action |

Inputs |

Default |

|---|---|---|

Position Onsite |

|

2h |

Jack-up |

depth, extensionspeed_above_depthspeed_below_depth |

calculated |

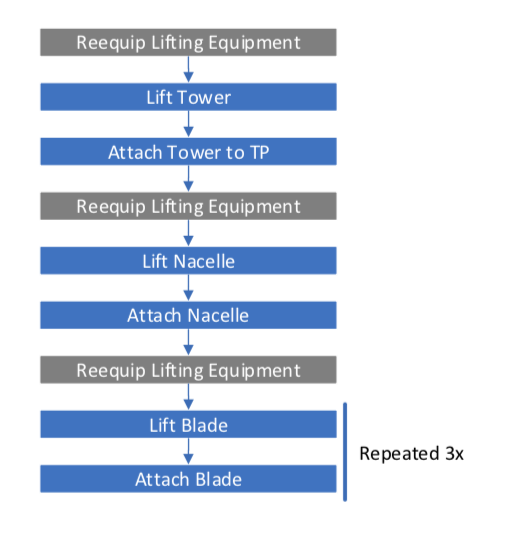

Turbine Installation

After site preperation is complete, the WTIV begins installation by releasing a turbine from its fastening (either on its own deck or neighboring feeder barge). The tower is then lifted into place using the WTIV crane and attached to the substructure. The nacelle is then released from its fastenings, lifted into place and attached to the tower. The same process is repeated for each of the three turbine blades. Inputs and process times are summarized in the following table.

Action |

Inputs |

Default |

|---|---|---|

Reequip Crane |

|

1h |

Release Tower |

|

3h |

Lift Tower |

turbine.hub_heightwtiv.crane_ratewave_height |

calculated |

Attach Tower |

|

6h |

Release Nacelle |

|

3h |

Lift Nacelle |

turbine.hub_heightwtiv.crane_ratewave_height |

calculated |

Attach Nacelle |

|

6h |

Release Blade |

|

1h |

Lift Blade |

turbine.hub_heightwtiv.crane_ratewave_height |

calculated |

Attach Blade |

|

3.5h |

Process Diagrams

Single WTIV Installation

WTIV with Feeder Barges Installation

Component Installation