Demonstration of the Available Metrics#

For a complete list of metrics and their documentation, please see the API Metrics documentation.

This demonstration will rely on the results produced in the "How To" notebook and serves as an extension of the API documentation to show what the results will look like depending on what inputs are provided.

A Jupyter notebook of this tutorial can be run from

examples/metrics_demonstration.ipynb locally, or through

binder.

from pprint import pprint

from functools import partial

import pandas as pd

from pandas.io.formats.style import Styler

from wombat.core import Simulation, Metrics

from wombat.utilities import plot

# Clean up the aesthetics for the pandas outputs

pd.set_option("display.max_rows", 30)

pd.set_option("display.max_columns", 10)

style = partial(

Styler,

table_attributes='style="font-size: 14px; grid-column-count: 6"',

precision=2,

thousands=",",

)

Table of Contents#

Below is a list of top-level sections to demonstrate how to use WOMBAT's Metrics

class methods and an explanation of each individual metric.

If you don't see a metric or result computation that is core to your work, please submit an issue with details on what the metric is, and how it should be computed.

Setup: Running a simulation to gather the results

Common Parameters: Explanation of frequently used parameter settings

Availability: Time-based and energy-based availability

Capacity Factor: Gross and net capacity factor

Task Completion Rate: Task completion metrics

Equipment Costs: Cost breakdowns by servicing equipment

Service Equipment Utilization Rate: Utilization of servicing equipment

Vessel-Crew Hours at Sea: Number of crew or vessel hours spent at sea

Number of Tows: Number of tows breakdowns

Dispatch Summary: Mobilization and charter period breakdown

Labor Costs: Breakdown of labor costs

Equipment and Labor Costs: Combined servicing equipment and labor cost breakdown

Emissions: Emissions of servicing equipment based on activity

Component Costs: Materials costs

Fixed Cost Impacts: Total fixed costs

OpEx: Project OpEx

Process Times: Timing of various stages of repair and maintenance

Request Summary: Total number of submitted, canceled, and completed repair and maintenance tasks

Power Production: Energy production, in GWh, MWh, or kWh

H2 Production: Produced Hydrogen, in kg/hr or t/hr

Net Present Value: Project NPV calculator

Setup#

The simulations from the How To notebook are going to be rerun as it is not recommended to create a Metrics class from scratch due to the large number of inputs that are required, and the initialization is provided in the simulation API's run method.

To simplify this process, a feature has been added to save the simulation outputs required to generate the Metrics inputs and a method to reload those outputs as inputs.

sim = Simulation("COREWIND", "morro_bay_in_situ.yaml")

# Both of these parameters are True by default for convenience

sim.run(create_metrics=True, save_metrics_inputs=True)

# Load the metrics data

fpath = sim.env.metrics_input_fname.parent

fname = sim.env.metrics_input_fname.name

metrics = Metrics.from_simulation_outputs(fpath, fname)

# Delete the log files now that they're loaded in

sim.env.cleanup_log_files()

# Alternatively, in this case because the simulation was run, we can use the

# following for convenience convenience only

metrics = sim.metrics

Common Parameter Explanations#

Before diving into each and every metric, and how they can be customized, it is worth noting some of the most common parameters used throughout, and their meanings to reduce redundancy. The varying output forms are demonstrated in the availability section below.

frequency#

- project

Computed across the whole simulation, with the resulting

DataFramehaving an empty index.- annual

Summary of each year in the simulation, with the resulting

DataFramehaving "year" as the index.- monthly

Summary of each month of the year, aggregated across years, with the resulting

DataFramehaving "month" as the index.- month-year

computed on a month-by-year basis, producing the results for every month of the simulation, with the resulting

DataFramehaving "year" and "month" as the index.

by#

- windfarm

Aggregated across all turbines, with the resulting

DataFramehaving only "windfarm" as a column.- turbine

Computed for each turbine, with the resulting

DataFramehaving a column for each turbine.- electrolyzer

Computed for each electrolyzer, with the resulting

DataFramehaving a column for each electrolyzer. This option is only available for the availability and capacity factor metrics.

Availability#

There are two methods to produce availability, which have their own function calls:

energy: actual power produced divided by potential power produced

time: The ratio of all non-zero hours to all hours in the simulation, or the proportion of the simulation where turbines are operating

Here, we will go through the various input definitions to get time-based availability data as both methods use the same inputs, and provide outputs in the same format.

Inputs:

frequency, as explained above options: "project", "annual", "monthly", and "month-year"by, as explained above options: "windfarm", "turbine", or "electrolyzer"

Below is a demonstration of the variations on frequency and by for

time_based_availability.

style(metrics.time_based_availability(frequency="project", by="windfarm"))

| windfarm | |

|---|---|

| time_availability | 0.91 |

style(metrics.production_based_availability(frequency="project", by="windfarm"))

| windfarm | |

|---|---|

| energy_availability | 0.91 |

Note that in the two above examples, that the values are equal. This is due to the fact that the example simulation does not have any operating reduction applied to failures, unless it's a catastrophic failure, so there is no expected difference.

# Demonstrate the by turbine granularity

style(metrics.time_based_availability(frequency="project", by="turbine"))

| WTG_0000 | WTG_0001 | WTG_0002 | WTG_0003 | WTG_0004 | WTG_0005 | WTG_0006 | WTG_0007 | WTG_0008 | WTG_0009 | WTG_0100 | WTG_0101 | WTG_0102 | WTG_0103 | WTG_0104 | WTG_0105 | WTG_0106 | WTG_0107 | WTG_0108 | WTG_0109 | WTG_0200 | WTG_0201 | WTG_0202 | WTG_0203 | WTG_0204 | WTG_0205 | WTG_0206 | WTG_0207 | WTG_0208 | WTG_0209 | WTG_0300 | WTG_0301 | WTG_0302 | WTG_0303 | WTG_0304 | WTG_0305 | WTG_0306 | WTG_0307 | WTG_0308 | WTG_0309 | WTG_0400 | WTG_0401 | WTG_0402 | WTG_0403 | WTG_0404 | WTG_0405 | WTG_0406 | WTG_0407 | WTG_0408 | WTG_0409 | WTG_0500 | WTG_0501 | WTG_0502 | WTG_0503 | WTG_0504 | WTG_0505 | WTG_0506 | WTG_0507 | WTG_0508 | WTG_0509 | WTG_0600 | WTG_0601 | WTG_0602 | WTG_0603 | WTG_0604 | WTG_0605 | WTG_0606 | WTG_0607 | WTG_0608 | WTG_0609 | WTG_0700 | WTG_0701 | WTG_0702 | WTG_0703 | WTG_0704 | WTG_0705 | WTG_0706 | WTG_0707 | WTG_0708 | WTG_0709 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| time_availability | 0.91 | 0.91 | 0.92 | 0.91 | 0.93 | 0.91 | 0.91 | 0.90 | 0.91 | 0.90 | 0.90 | 0.90 | 0.91 | 0.91 | 0.91 | 0.90 | 0.91 | 0.91 | 0.91 | 0.92 | 0.91 | 0.91 | 0.90 | 0.92 | 0.90 | 0.92 | 0.91 | 0.90 | 0.92 | 0.91 | 0.90 | 0.91 | 0.92 | 0.92 | 0.92 | 0.91 | 0.92 | 0.91 | 0.91 | 0.90 | 0.91 | 0.91 | 0.89 | 0.89 | 0.91 | 0.88 | 0.91 | 0.92 | 0.91 | 0.91 | 0.92 | 0.90 | 0.92 | 0.91 | 0.91 | 0.92 | 0.91 | 0.92 | 0.92 | 0.92 | 0.91 | 0.92 | 0.91 | 0.91 | 0.91 | 0.91 | 0.90 | 0.90 | 0.91 | 0.92 | 0.91 | 0.89 | 0.90 | 0.91 | 0.91 | 0.91 | 0.90 | 0.92 | 0.92 | 0.91 |

# Demonstrate the annualized outputs

style(metrics.time_based_availability(frequency="annual", by="windfarm"))

| windfarm | |

|---|---|

| year | |

| 2002 | 0.95 |

| 2003 | 0.92 |

| 2004 | 0.92 |

| 2005 | 0.91 |

| 2006 | 0.86 |

| 2007 | 0.90 |

| 2008 | 0.91 |

| 2009 | 0.92 |

| 2010 | 0.87 |

| 2011 | 0.89 |

| 2012 | 0.91 |

| 2013 | 0.93 |

| 2014 | 0.91 |

| 2015 | 0.94 |

| 2016 | 0.91 |

| 2017 | 0.91 |

| 2018 | 0.92 |

| 2019 | 0.90 |

| 2020 | 0.92 |

| 2021 | 0.89 |

# Demonstrate the month aggregations

style(metrics.time_based_availability(frequency="monthly", by="windfarm"))

| windfarm | |

|---|---|

| month | |

| 1 | 0.89 |

| 2 | 0.84 |

| 3 | 0.88 |

| 4 | 0.86 |

| 5 | 0.88 |

| 6 | 0.92 |

| 7 | 0.93 |

| 8 | 0.95 |

| 9 | 0.95 |

| 10 | 0.94 |

| 11 | 0.94 |

| 12 | 0.92 |

# Demonstrate the granular monthly reporting

style(metrics.time_based_availability(frequency="month-year", by="windfarm"))

| windfarm | ||

|---|---|---|

| year | month | |

| 2002 | 1 | 0.94 |

| 2 | 0.89 | |

| 3 | 0.96 | |

| 4 | 0.97 | |

| 5 | 0.94 | |

| 6 | 0.96 | |

| 7 | 0.98 | |

| 8 | 0.98 | |

| 9 | 0.98 | |

| 10 | 0.98 | |

| 11 | 0.94 | |

| 12 | 0.93 | |

| 2003 | 1 | 0.83 |

| 2 | 0.90 | |

| 3 | 0.90 | |

| 4 | 0.90 | |

| 5 | 0.90 | |

| 6 | 0.90 | |

| 7 | 0.90 | |

| 8 | 0.97 | |

| 9 | 0.98 | |

| 10 | 0.95 | |

| 11 | 0.95 | |

| 12 | 0.92 | |

| 2004 | 1 | 0.86 |

| 2 | 0.89 | |

| 3 | 0.88 | |

| 4 | 0.89 | |

| 5 | 0.90 | |

| 6 | 0.90 | |

| 7 | 0.95 | |

| 8 | 0.98 | |

| 9 | 0.97 | |

| 10 | 0.95 | |

| 11 | 0.96 | |

| 12 | 0.93 | |

| 2005 | 1 | 0.70 |

| 2 | 0.92 | |

| 3 | 0.90 | |

| 4 | 0.91 | |

| 5 | 0.91 | |

| 6 | 0.91 | |

| 7 | 0.96 | |

| 8 | 0.98 | |

| 9 | 0.96 | |

| 10 | 0.93 | |

| 11 | 0.96 | |

| 12 | 0.94 | |

| 2006 | 1 | 0.73 |

| 2 | 0.30 | |

| 3 | 0.88 | |

| 4 | 0.89 | |

| 5 | 0.89 | |

| 6 | 0.89 | |

| 7 | 0.90 | |

| 8 | 0.92 | |

| 9 | 0.96 | |

| 10 | 0.96 | |

| 11 | 0.96 | |

| 12 | 0.92 | |

| 2007 | 1 | 0.91 |

| 2 | 0.57 | |

| 3 | 0.92 | |

| 4 | 0.90 | |

| 5 | 0.90 | |

| 6 | 0.90 | |

| 7 | 0.90 | |

| 8 | 0.90 | |

| 9 | 0.98 | |

| 10 | 0.96 | |

| 11 | 0.96 | |

| 12 | 0.93 | |

| 2008 | 1 | 0.94 |

| 2 | 0.78 | |

| 3 | 0.89 | |

| 4 | 0.93 | |

| 5 | 0.89 | |

| 6 | 0.90 | |

| 7 | 0.90 | |

| 8 | 0.89 | |

| 9 | 0.94 | |

| 10 | 0.95 | |

| 11 | 0.96 | |

| 12 | 0.95 | |

| 2009 | 1 | 0.94 |

| 2 | 0.83 | |

| 3 | 0.91 | |

| 4 | 0.91 | |

| 5 | 0.92 | |

| 6 | 0.93 | |

| 7 | 0.90 | |

| 8 | 0.94 | |

| 9 | 0.95 | |

| 10 | 0.93 | |

| 11 | 0.93 | |

| 12 | 0.92 | |

| 2010 | 1 | 0.92 |

| 2 | 0.86 | |

| 3 | 0.56 | |

| 4 | 0.71 | |

| 5 | 0.96 | |

| 6 | 0.92 | |

| 7 | 0.90 | |

| 8 | 0.93 | |

| 9 | 0.93 | |

| 10 | 0.91 | |

| 11 | 0.91 | |

| 12 | 0.93 | |

| 2011 | 1 | 0.93 |

| 2 | 0.88 | |

| 3 | 0.72 | |

| 4 | 0.72 | |

| 5 | 0.94 | |

| 6 | 0.94 | |

| 7 | 0.92 | |

| 8 | 0.93 | |

| 9 | 0.92 | |

| 10 | 0.92 | |

| 11 | 0.92 | |

| 12 | 0.93 | |

| 2012 | 1 | 0.93 |

| 2 | 0.91 | |

| 3 | 0.90 | |

| 4 | 0.77 | |

| 5 | 0.94 | |

| 6 | 0.91 | |

| 7 | 0.96 | |

| 8 | 0.93 | |

| 9 | 0.92 | |

| 10 | 0.93 | |

| 11 | 0.93 | |

| 12 | 0.90 | |

| 2013 | 1 | 0.88 |

| 2 | 0.90 | |

| 3 | 0.90 | |

| 4 | 0.86 | |

| 5 | 0.96 | |

| 6 | 0.94 | |

| 7 | 0.97 | |

| 8 | 0.96 | |

| 9 | 0.93 | |

| 10 | 0.92 | |

| 11 | 0.94 | |

| 12 | 0.94 | |

| 2014 | 1 | 0.91 |

| 2 | 0.94 | |

| 3 | 0.92 | |

| 4 | 0.73 | |

| 5 | 0.93 | |

| 6 | 0.95 | |

| 7 | 0.97 | |

| 8 | 0.97 | |

| 9 | 0.95 | |

| 10 | 0.92 | |

| 11 | 0.90 | |

| 12 | 0.89 | |

| 2015 | 1 | 0.91 |

| 2 | 0.92 | |

| 3 | 0.96 | |

| 4 | 0.91 | |

| 5 | 0.91 | |

| 6 | 0.96 | |

| 7 | 0.98 | |

| 8 | 0.98 | |

| 9 | 0.94 | |

| 10 | 0.94 | |

| 11 | 0.91 | |

| 12 | 0.90 | |

| 2016 | 1 | 0.89 |

| 2 | 0.90 | |

| 3 | 0.90 | |

| 4 | 0.88 | |

| 5 | 0.84 | |

| 6 | 0.91 | |

| 7 | 0.96 | |

| 8 | 0.97 | |

| 9 | 0.94 | |

| 10 | 0.93 | |

| 11 | 0.90 | |

| 12 | 0.89 | |

| 2017 | 1 | 0.89 |

| 2 | 0.90 | |

| 3 | 0.90 | |

| 4 | 0.87 | |

| 5 | 0.84 | |

| 6 | 0.89 | |

| 7 | 0.91 | |

| 8 | 0.96 | |

| 9 | 0.97 | |

| 10 | 0.94 | |

| 11 | 0.95 | |

| 12 | 0.91 | |

| 2018 | 1 | 0.92 |

| 2 | 0.90 | |

| 3 | 0.91 | |

| 4 | 0.79 | |

| 5 | 0.90 | |

| 6 | 0.92 | |

| 7 | 0.96 | |

| 8 | 0.96 | |

| 9 | 0.96 | |

| 10 | 0.96 | |

| 11 | 0.96 | |

| 12 | 0.91 | |

| 2019 | 1 | 0.89 |

| 2 | 0.90 | |

| 3 | 0.90 | |

| 4 | 0.86 | |

| 5 | 0.67 | |

| 6 | 0.90 | |

| 7 | 0.92 | |

| 8 | 0.97 | |

| 9 | 0.96 | |

| 10 | 0.97 | |

| 11 | 0.95 | |

| 12 | 0.93 | |

| 2020 | 1 | 0.89 |

| 2 | 0.86 | |

| 3 | 0.83 | |

| 4 | 0.91 | |

| 5 | 0.88 | |

| 6 | 0.92 | |

| 7 | 0.93 | |

| 8 | 0.96 | |

| 9 | 0.98 | |

| 10 | 0.97 | |

| 11 | 0.97 | |

| 12 | 0.92 | |

| 2021 | 1 | 0.89 |

| 2 | 0.90 | |

| 3 | 0.90 | |

| 4 | 0.89 | |

| 5 | 0.57 | |

| 6 | 0.88 | |

| 7 | 0.90 | |

| 8 | 0.95 | |

| 9 | 0.96 | |

| 10 | 0.95 | |

| 11 | 0.95 | |

| 12 | 0.94 |

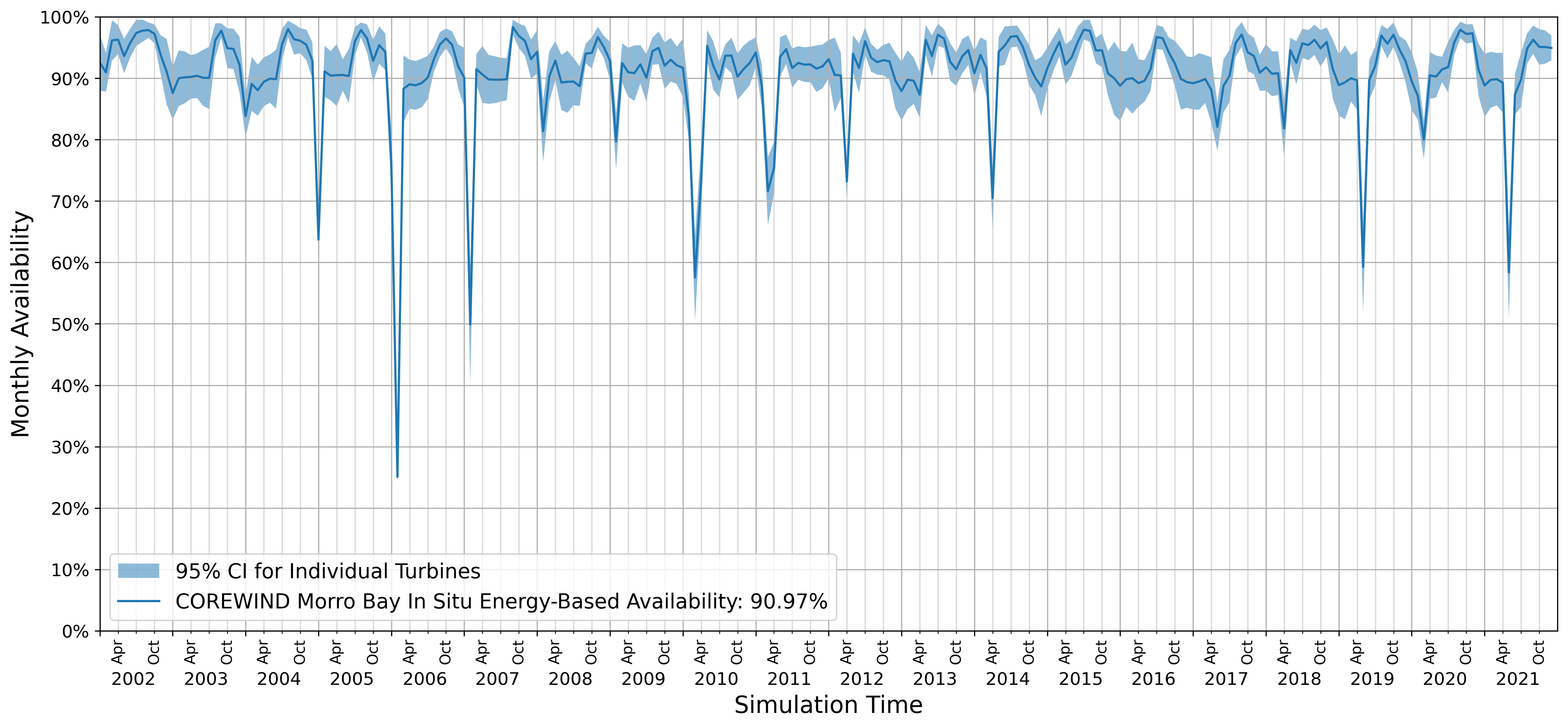

Plotting Availability#

As of v0.9, the ability to plot the wind farm and turbine availability has been enabled as an experimental feature. Please see the plotting API documentation for more details.

# Demonstrate the granular monthly reporting

plot.plot_farm_availability(sim=sim, which="energy", farm_95_CI=True)

Capacity Factor#

The capacity factor is the ratio of actual (net) or potential (gross) energy production

divided by the project's capacity. For further documentation, see the API docs here:

wombat.core.post_processor.Metrics.capacity_factor().

Inputs:

which"net": net capacity factor, actual production divided by the plant capacity

"gross": gross capacity factor, potential production divided by the plant capacity

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"by, as explained above, options: "windfarm", "turbine", and "electrolyzer"

Example Usage:

net_cf = metrics.capacity_factor(which="net", frequency="project", by="windfarm").squeeze()

gross_cf = metrics.capacity_factor(which="gross", frequency="project", by="windfarm").squeeze()

print(f" Net capacity factor: {net_cf:.2%}")

print(f"Gross capacity factor: {gross_cf:.2%}")

Net capacity factor: 50.57%

Gross capacity factor: 55.59%

Task Completion Rate#

The task completion rate is the ratio of tasks completed aggregated to the desired

frequency. It is possible to have a >100% completion rate if all maintenance and

failure requests submitted in a time period were completed in addition to those that

went unfinished in prior time periods. For further documentation, see the API docs here:

wombat.core.post_processor.Metrics.task_completion_rate().

Inputs:

which"scheduled": scheduled maintenance only (classified as maintenance tasks in inputs)

"unscheduled": unscheduled maintenance only (classified as failure events in inputs)

"both": Combined completion rate for all tasks

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"

Example Usage:

scheduled = metrics.task_completion_rate(which="scheduled", frequency="project").values[0][0]

unscheduled = metrics.task_completion_rate(which="unscheduled", frequency="project").values[0][0]

combined = metrics.task_completion_rate(which="both", frequency="project").values[0][0]

print(f" Scheduled Task Completion Rate: {scheduled:.2%}")

print(f"Unscheduled Task Completion Rate: {unscheduled:.2%}")

print(f" Overall Task Completion Rate: {combined:.2%}")

Scheduled Task Completion Rate: 95.97%

Unscheduled Task Completion Rate: 96.06%

Overall Task Completion Rate: 96.03%

Equipment Costs#

Sum of the costs associated with a simulation's servicing equipment, which excludes

materials, downtime, etc. For further documentation, see the API docs here:

wombat.core.post_processor.Metrics.equipment_costs().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"by_equipmentTrue: Aggregates all equipment into a single costFalse: Computes for each unit of servicing equipment

Example Usage:

# Project total at the whole wind farm level

style(metrics.equipment_costs(frequency="project", by_equipment=False))

| equipment_cost | |

|---|---|

| 0 | 2,312,786,480.88 |

# Project totals at servicing equipment level

style(metrics.equipment_costs(frequency="project", by_equipment=True))

| Anchor Handling Tug | Cable Laying Vessel | Crew Transfer Vessel 1 | Crew Transfer Vessel 2 | Crew Transfer Vessel 3 | Crew Transfer Vessel 4 | Crew Transfer Vessel 5 | Crew Transfer Vessel 6 | Crew Transfer Vessel 7 | Diving Support Vessel | Heavy Lift Vessel | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 123,663,086.59 | 176,907,856.41 | 25,563,175.43 | 25,563,192.62 | 25,563,193.01 | 25,563,192.06 | 25,563,168.54 | 25,563,196.25 | 25,563,182.09 | 117,082,811.25 | 1,716,190,426.63 |

Service Equipment Utilization Rate#

Ratio of days when the servicing equipment is in use (not delayed for a whole day due to

either weather or lack of repairs to be completed) to the number of days it's present in

the simulation. For further documentation, see the API docs here:

wombat.core.post_processor.Metrics.service_equipment_utilization().

Inputs:

frequency, as explained above, options: "project" and "annual"

Example Usage:

# Project totals

style(metrics.service_equipment_utilization(frequency="project"))

| Anchor Handling Tug | Cable Laying Vessel | Crew Transfer Vessel 1 | Crew Transfer Vessel 2 | Crew Transfer Vessel 3 | Crew Transfer Vessel 4 | Crew Transfer Vessel 5 | Crew Transfer Vessel 6 | Crew Transfer Vessel 7 | Diving Support Vessel | Heavy Lift Vessel | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.92 | 0.96 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 0.96 | 1.00 |

Vessel-Crew Hours at Sea#

The number of vessel hours or crew hours at sea for offshore wind power plant

simulations. For further documentation, see the API docs here:

wombat.core.post_processor.Metrics.vessel_crew_hours_at_sea().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"by_equipmentTrue: Aggregates all equipment into a single costFalse: Computes for each unit of servicing equipment

vessel_crew_assumption: A dictionary of vessel names (ServiceEquipment.settings.name, but also found atMetrics.service_equipment_names) and the number of crew onboard at any given time. The application of this assumption transforms the results from vessel hours at sea to crew hours at sea.

Example Usage:

# Project total, not broken out by vessel

style(metrics.vessel_crew_hours_at_sea(frequency="project", by_equipment=False))

| Total Crew Hours at Sea | |

|---|---|

| 0 | 675,664.00 |

# Annual project totals, broken out by vessel

style(metrics.vessel_crew_hours_at_sea(frequency="annual", by_equipment=True))

---------------------------------------------------------------------------

KeyError Traceback (most recent call last)

Cell In[16], line 2

1 # Annual project totals, broken out by vessel

----> 2 style(metrics.vessel_crew_hours_at_sea(frequency="annual", by_equipment=True))

File /opt/hostedtoolcache/Python/3.13.11/x64/lib/python3.13/site-packages/wombat/core/post_processor.py:1028, in Metrics.vessel_crew_hours_at_sea(self, frequency, by_equipment, vessel_crew_assumption)

1022 return pd.DataFrame(at_sea.sum()[["duration"]]).T.rename(

1023 columns={"duration": "Total Crew Hours at Sea"}

1024 )

1025 additional_cols = frequency.group_cols

1026 total_hours = (

1027 total_hours.drop(columns=frequency.drop_cols)

-> 1028 .groupby(group_cols)[["N"]]

1029 .sum()

1030 )

1032 columns = additional_cols + columns

1033 group_cols.extend(additional_cols)

File /opt/hostedtoolcache/Python/3.13.11/x64/lib/python3.13/site-packages/pandas/core/frame.py:9210, in DataFrame.groupby(self, by, axis, level, as_index, sort, group_keys, observed, dropna)

9207 if level is None and by is None:

9208 raise TypeError("You have to supply one of 'by' and 'level'")

-> 9210 return DataFrameGroupBy(

9211 obj=self,

9212 keys=by,

9213 axis=axis,

9214 level=level,

9215 as_index=as_index,

9216 sort=sort,

9217 group_keys=group_keys,

9218 observed=observed,

9219 dropna=dropna,

9220 )

File /opt/hostedtoolcache/Python/3.13.11/x64/lib/python3.13/site-packages/pandas/core/groupby/groupby.py:1331, in GroupBy.__init__(self, obj, keys, axis, level, grouper, exclusions, selection, as_index, sort, group_keys, observed, dropna)

1328 self.dropna = dropna

1330 if grouper is None:

-> 1331 grouper, exclusions, obj = get_grouper(

1332 obj,

1333 keys,

1334 axis=axis,

1335 level=level,

1336 sort=sort,

1337 observed=False if observed is lib.no_default else observed,

1338 dropna=self.dropna,

1339 )

1341 if observed is lib.no_default:

1342 if any(ping._passed_categorical for ping in grouper.groupings):

File /opt/hostedtoolcache/Python/3.13.11/x64/lib/python3.13/site-packages/pandas/core/groupby/grouper.py:1043, in get_grouper(obj, key, axis, level, sort, observed, validate, dropna)

1041 in_axis, level, gpr = False, gpr, None

1042 else:

-> 1043 raise KeyError(gpr)

1044 elif isinstance(gpr, Grouper) and gpr.key is not None:

1045 # Add key to exclusions

1046 exclusions.add(gpr.key)

KeyError: 'agent'

Number of Tows#

The number of tows performed during the simulation. If tow-to-port was not used in the

simulation, a DataFrame with a single value of 0 will be returned. For further

documentation, see the API docs here:

wombat.core.post_processor.Metrics.number_of_tows().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"by_tugTrue: Computed for each tugboat (towing vessel)False: Aggregates all the tugboats

by_directionTrue: Computed for each direction a tow was performed (to port or to site)False: Aggregates to the total number of tows

Example Usage:

# Project Total

# NOTE: This example has no towing, so it will return 0

style(metrics.number_of_tows(frequency="project"))

| total_tows | |

|---|---|

| 0 | 0 |

Dispatch Summary#

The number of mobilizations and the average length of their charter during the

simulation for each piece of servicing equipment. For further documentation, see the API

docs here: wombat.core.post_processor.Metrics.dispatch_summary().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"

Example Usage:

# Project Total

style(metrics.dispatch_summary(frequency="project"))

| N Mobilizations | Average Charter Days | |

|---|---|---|

| agent | ||

| Anchor Handling Tug | 52 | 28.00 |

| Cable Laying Vessel | 43 | 51.86 |

| Crew Transfer Vessel 1 | 1 | 7,303.00 |

| Crew Transfer Vessel 2 | 1 | 7,303.67 |

| Crew Transfer Vessel 3 | 1 | 7,303.00 |

| Crew Transfer Vessel 4 | 1 | 7,303.00 |

| Crew Transfer Vessel 5 | 1 | 7,303.00 |

| Crew Transfer Vessel 6 | 1 | 7,303.00 |

| Crew Transfer Vessel 7 | 1 | 7,303.00 |

| Diving Support Vessel | 154 | 7.09 |

| Heavy Lift Vessel | 153 | 37.46 |

Labor Costs#

Sum of all labor costs associated with servicing equipment, excluding the labor defined

in the fixed costs, which can be broken out by type. For further documentation, see the

API docs here: wombat.core.post_processor.Metrics.labor_costs().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"by_typeTrue: Computed for each labor type (salary and hourly)False: Aggregates all the labor costs

Example Usage:

# Project total at the whole wind farm level

total = metrics.labor_costs(frequency="project", by_type=False)

print(f"Project total: ${total.values[0][0] / metrics.project_capacity:,.2f}/MW")

Project total: $41,995.89/MW

# Project totals for each type of labor

style(metrics.labor_costs(frequency="project", by_type=True))

| hourly_labor_cost | salary_labor_cost | total_labor_cost | |

|---|---|---|---|

| 0 | 0.00 | 50,395,071.70 | 50,395,071.70 |

Equipment and Labor Costs#

Sum of all labor and servicing equipment costs, excluding the labor defined in the fixed

costs, which can be broken out by each category. For further documentation, see the API

docs here: wombat.core.post_processor.Metrics.equipment_labor_cost_breakdown().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"by_categoryTrue: Computed for each unit servicing equipment and labor categoryFalse: Aggregated to the sum of all costs

reason definitions:

Maintenance: routine maintenance, or events defined as a

wombat.core.data_classes.MaintenanceRepair: unscheduled maintenance, ranging from inspections to replacements, or events defined as a

wombat.core.data_classes.FailureMobilization: Cost of mobilizing servicing equipment

Crew Transfer: Costs incurred while crew are transferring between a turbine or substation and the servicing equipment

Site Travel: Costs incurred while transiting to/from the site and while at the site

Weather Delay: Any delays caused by unsafe weather conditions

No Requests: Equipment and labor is active, but there are no repairs or maintenance tasks to be completed

Not in Shift: Any time outside the operating hours of the wind farm (or the servicing equipment's specific operating hours)

Example Usage:

# Project totals

style(metrics.equipment_labor_cost_breakdowns(frequency="project", by_category=False))

| total_cost | total_hours | |

|---|---|---|

| reason | ||

| Maintenance | 23,896,314.18 | 73,440.00 |

| Repair | 604,794,480.18 | 165,377.64 |

| Crew Transfer | 9,132,004.44 | 11,207.50 |

| Site Travel | 103,009,576.78 | 123,059.44 |

| Mobilization | 122,160,000.00 | 132,168.00 |

| Weather Delay | 1,396,031,103.66 | 600,634.81 |

| No Requests | 74,906,997.04 | 400,136.88 |

| Not in Shift | 29,251,076.30 | 106,041.72 |

# Project totals by each category

style(metrics.equipment_labor_cost_breakdowns(frequency="project", by_category=True))

| hourly_labor_cost | salary_labor_cost | total_labor_cost | equipment_cost | total_cost | total_hours | |

|---|---|---|---|---|---|---|

| reason | ||||||

| Maintenance | 0 | 2,246,814.18 | 2,246,814.18 | 21,649,500.00 | 23,896,314.18 | 73,440.00 |

| Repair | 0 | 7,927,971.89 | 7,927,971.89 | 596,866,508.29 | 604,794,480.18 | 165,377.64 |

| Crew Transfer | 0 | 352,363.81 | 352,363.81 | 8,779,640.62 | 9,132,004.44 | 11,207.50 |

| Site Travel | 0 | 3,901,974.91 | 3,901,974.91 | 99,107,601.87 | 103,009,576.78 | 123,059.44 |

| Mobilization | 0 | 0.00 | 0.00 | 122,160,000.00 | 122,160,000.00 | 132,168.00 |

| Weather Delay | 0 | 21,886,753.63 | 21,886,753.63 | 1,374,144,350.03 | 1,396,031,103.66 | 600,634.81 |

| No Requests | 0 | 11,004,284.87 | 11,004,284.87 | 63,902,712.17 | 74,906,997.04 | 400,136.88 |

| Not in Shift | 0 | 3,074,908.40 | 3,074,908.40 | 26,176,167.90 | 29,251,076.30 | 106,041.72 |

Emissions#

Emissions (tons or other provided units) of all servicing equipment activity, except

overnight waiting periods between shifts. For further documentation, see the API docs

here: wombat.core.post_processor.Metrics.emissions().

Inputs:

emissions_factors: Dictionary of servicing equipment names and the emissions per hour of the following activities:transit,maneuvering,idle at site, andidle at port, where port is stand-in for wherever the servicing equipment might be based when not at site.maneuvering_factor: The proportion of transit time that can generally be associated with positioning servicing, by default 10%.port_engine_on_factor: The proportion of the idling at port time when the engine is running and producing emissions, by default 25%.

# Create the emissions factors, in tons per hour

emissions_factors = {

"Crew Transfer Vessel 1": {

"transit": 4,

"maneuvering": 3,

"idle at site": 0.5,

"idle at port": 0.25,

},

"Field Support Vessel": {

"transit": 6,

"maneuvering": 4,

"idle at site": 1,

"idle at port": 0.5,

},

"Heavy Lift Vessel": {

"transit": 12,

"maneuvering": 7,

"idle at site": 1,

"idle at port": 0.5,

},

"Diving Support Vessel": {

"transit": 4,

"maneuvering": 7,

"idle at site": 0.2,

"idle at port": 0.2,

},

"Cable Laying Vessel": {

"transit": 4,

"maneuvering": 7,

"idle at site": 0.2,

"idle at port": 0.2,

},

"Anchor Handling Tug": {

"transit": 4,

"maneuvering": 3,

"idle at site": 1,

"idle at port": 0.25,

},

}

# Add in CTVs 2 through 7

for i in range(2, 8):

emissions_factors[f"Crew Transfer Vessel {i}"] = emissions_factors[f"Crew Transfer Vessel 1"]

style(metrics.emissions(emissions_factors=emissions_factors, maneuvering_factor=0.075, port_engine_on_factor=0.20))

| duration | distance_km | emissions | ||

|---|---|---|---|---|

| agent | category | |||

| Anchor Handling Tug | idle at port | 4,660.29 | 0.00 | 1,165.07 |

| idle at site | 33,544.71 | 0.00 | 33,544.71 | |

| maneuvering | 1,889.31 | 0.00 | 5,667.92 | |

| transit | 23,301.45 | inf | 93,205.78 | |

| Cable Laying Vessel | idle at port | 2,860.88 | 0.00 | 572.18 |

| idle at site | 46,305.32 | 0.00 | 9,261.06 | |

| maneuvering | 1,159.82 | 0.00 | 8,118.72 | |

| transit | 14,304.41 | inf | 57,217.65 | |

| Crew Transfer Vessel 1 | idle at port | 2,973.22 | 0.00 | 743.31 |

| idle at site | 31,199.69 | 0.00 | 15,599.85 | |

| maneuvering | 1,205.36 | 0.00 | 3,616.08 | |

| transit | 14,866.12 | inf | 59,464.49 | |

| Crew Transfer Vessel 2 | idle at port | 3,055.79 | 0.00 | 763.95 |

| idle at site | 32,049.66 | 0.00 | 16,024.83 | |

| maneuvering | 1,238.83 | 0.00 | 3,716.50 | |

| transit | 15,278.93 | inf | 61,115.71 | |

| Crew Transfer Vessel 3 | idle at port | 3,053.91 | 0.00 | 763.48 |

| idle at site | 32,465.80 | 0.00 | 16,232.90 | |

| maneuvering | 1,238.07 | 0.00 | 3,714.22 | |

| transit | 15,269.57 | inf | 61,078.28 | |

| Crew Transfer Vessel 4 | idle at port | 3,068.27 | 0.00 | 767.07 |

| idle at site | 31,872.78 | 0.00 | 15,936.39 | |

| maneuvering | 1,243.89 | 0.00 | 3,731.68 | |

| transit | 15,341.33 | inf | 61,365.34 | |

| Crew Transfer Vessel 5 | idle at port | 2,983.75 | 0.00 | 745.94 |

| idle at site | 31,385.27 | 0.00 | 15,692.63 | |

| maneuvering | 1,209.63 | 0.00 | 3,628.89 | |

| transit | 14,918.77 | inf | 59,675.08 | |

| Crew Transfer Vessel 6 | idle at port | 3,046.49 | 0.00 | 761.62 |

| idle at site | 32,049.88 | 0.00 | 16,024.94 | |

| maneuvering | 1,235.06 | 0.00 | 3,705.19 | |

| transit | 15,232.45 | inf | 60,929.78 | |

| Crew Transfer Vessel 7 | idle at port | 2,995.64 | 0.00 | 748.91 |

| idle at site | 31,276.21 | 0.00 | 15,638.10 | |

| maneuvering | 1,214.45 | 0.00 | 3,643.35 | |

| transit | 14,978.22 | inf | 59,912.89 | |

| Diving Support Vessel | idle at port | 11,357.88 | 0.00 | 2,271.58 |

| idle at site | 5,405.21 | 0.00 | 1,081.04 | |

| maneuvering | 4,604.55 | 0.00 | 32,231.82 | |

| transit | 56,789.39 | 124,386.98 | 227,157.58 | |

| Field Support Vessel | idle at port | 0.00 | 0.00 | 0.00 |

| idle at site | 0.00 | 0.00 | 0.00 | |

| maneuvering | 0.00 | 0.00 | 0.00 | |

| transit | 0.00 | 0.00 | 0.00 | |

| Heavy Lift Vessel | idle at port | 7,780.89 | 0.00 | 3,890.45 |

| idle at site | 109,320.99 | 0.00 | 109,320.99 | |

| maneuvering | 3,154.41 | 0.00 | 22,080.90 | |

| transit | 38,904.45 | inf | 466,853.42 |

Component Costs#

All the costs associated with maintenance and failure events during the simulation,

including delays incurred during the repair process, but excluding costs not directly

tied to a repair. For further documentation, see the API docs here:

wombat.core.post_processor.Metrics.component_costs().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"by_categoryTrue: Computed across each subassemblyFalse: (default) Aggregated to the sum of all subassemblies

by_actionTrue: Computed by each of "repair", "maintenance", and "delay", and is included in the MultiIndexFalse: (default) Aggregated as the sum of all actions

by_taskTrue: Computed by each repair and maintenance task for each subassemblyFalse: (default) Aggregated as the sum of all tasks

include_travelTrue: Include intrasite and port-to-site travel costs in the repair summary.False: (default) Exclude travel from the cost summary

action definitions:

maintenance: routine maintenance

repair: unscheduled maintenance, ranging from inspections to replacements

delay: Any delays caused by unsafe weather conditions or not being able to finish a process within a single shift

travel: Any travel to and from the site between shifts or traveling to the system for initial repair, including crew transfer time.

Example Usage:

# Project totals by component

style(metrics.component_costs(frequency="project", by_category=False, by_action=False))

| total_cost | |

|---|---|

| subassembly | |

| anchor | 48,642,846.27 |

| array cable | 175,863,978.65 |

| ballast pump | 126,897.39 |

| drive_train | 116,865,788.95 |

| electrical system | 36,985,958.72 |

| export cable | 7,057,225.42 |

| generator | 313,416,418.85 |

| hydraulic pitch system | 31,966,539.40 |

| mooring lines | 73,623,703.79 |

| power converter | 1,129,220,486.55 |

| rotor_blades | 74,761,589.91 |

| supporting_structure | 79,688,194.66 |

| transformer | 1,125,869.23 |

| yaw_system | 15,750,233.00 |

# Project totals by each category and action type

style(metrics.component_costs(frequency="project", by_category=True, by_action=True))

| materials_cost | total_labor_cost | equipment_cost | total_cost | ||

|---|---|---|---|---|---|

| subassembly | action | ||||

| anchor | delay | 0 | 384,192.41 | 11,568,892.86 | 11,953,085.27 |

| repair | 9,754,000 | 865,761.00 | 26,070,000.00 | 36,689,761.00 | |

| array cable | delay | 0 | 2,997,144.09 | 102,557,626.93 | 105,554,771.02 |

| repair | 7,400,000 | 1,786,257.11 | 61,122,950.52 | 70,309,207.63 | |

| ballast pump | delay | 0 | 11,768.19 | 62,640.57 | 74,408.77 |

| repair | 22,000 | 4,821.96 | 25,666.67 | 52,488.63 | |

| drive_train | delay | 0 | 724,232.35 | 85,934,329.79 | 86,658,562.15 |

| repair | 2,548,000 | 195,598.79 | 27,463,628.01 | 30,207,226.80 | |

| electrical system | delay | 0 | 652,971.45 | 26,181,356.12 | 26,834,327.57 |

| repair | 790,000 | 181,006.15 | 9,180,625.00 | 10,151,631.15 | |

| export cable | delay | 0 | 179,292.48 | 6,135,110.84 | 6,314,403.32 |

| maintenance | 9,500 | 20,822.10 | 712,500.00 | 742,822.10 | |

| generator | delay | 0 | 5,062,479.04 | 223,807,158.12 | 228,869,637.16 |

| maintenance | 2,143,500 | 939,624.66 | 5,001,500.00 | 8,084,624.66 | |

| repair | 5,286,040 | 553,412.40 | 70,622,704.63 | 76,462,157.03 | |

| hydraulic pitch system | delay | 0 | 3,394,212.92 | 19,265,577.63 | 22,659,790.55 |

| repair | 1,121,300 | 873,240.52 | 7,312,208.33 | 9,306,748.85 | |

| mooring lines | delay | 0 | 1,535,867.74 | 25,651,127.13 | 27,186,994.87 |

| repair | 7,439,000 | 1,441,658.91 | 37,556,050.01 | 46,436,708.92 | |

| power converter | delay | 0 | 4,120,055.83 | 779,768,907.02 | 783,888,962.85 |

| repair | 8,719,000 | 1,543,216.52 | 335,069,307.18 | 345,331,523.70 | |

| rotor_blades | delay | 0 | 1,487,741.51 | 48,214,694.59 | 49,702,436.10 |

| repair | 5,300,784 | 407,043.53 | 19,351,326.27 | 25,059,153.80 | |

| supporting_structure | delay | 0 | 3,900,601.93 | 57,572,711.83 | 61,473,313.76 |

| maintenance | 1,151,000 | 1,261,380.90 | 15,802,500.00 | 18,214,880.90 | |

| transformer | delay | 0 | 145,555.94 | 774,775.38 | 920,331.32 |

| maintenance | 19,000 | 24,986.52 | 133,000.00 | 176,986.52 | |

| repair | 14,000 | 2,301.39 | 12,250.00 | 28,551.39 | |

| yaw_system | delay | 0 | 343,901.74 | 12,118,885.99 | 12,462,787.73 |

| repair | 134,000 | 73,653.61 | 3,079,791.67 | 3,287,445.28 |

Fixed Cost Impacts#

Computes the total costs of the fixed costs categories. For further documentation, see

the definition docs, here: wombat.core.data_classes.FixedCosts, or the API

docs here: wombat.core.post_processor.Metrics.fixed_costs().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"resolution(also, demonstrated below)"high": Computed across the most granular cost levels

"medium": Computed for each general cost category

"low": Aggregated to a single sum of costs

pprint(metrics.fixed_costs.hierarchy)

{'operations': {'annual_leases_fees': ['submerge_land_lease_costs',

'transmission_charges_rights'],

'environmental_health_safety_monitoring': [],

'insurance': ['brokers_fee',

'operations_all_risk',

'business_interruption',

'third_party_liability',

'storm_coverage'],

'labor': [],

'onshore_electrical_maintenance': [],

'operating_facilities': [],

'operations_management_administration': ['project_management_administration',

'marine_management',

'weather_forecasting',

'condition_monitoring']}}

Example Usage:

# Project totals at the highest level

# NOTE: there were no fixed costs defined in this example, so all values will be 0, so

# this will just be demonstrating the output format

style(metrics.project_fixed_costs(frequency="project", resolution="low"))

| operations | |

|---|---|

| 0 | 0.00 |

# Project totals at the medium level

style(metrics.project_fixed_costs(frequency="project", resolution="medium"))

| operations_management_administration | insurance | annual_leases_fees | operating_facilities | environmental_health_safety_monitoring | onshore_electrical_maintenance | labor | |

|---|---|---|---|---|---|---|---|

| 0 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

# Project totals at the lowest level

style(metrics.project_fixed_costs(frequency="project", resolution="high"))

| project_management_administration | marine_management | weather_forecasting | condition_monitoring | brokers_fee | operations_all_risk | business_interruption | third_party_liability | storm_coverage | submerge_land_lease_costs | transmission_charges_rights | operating_facilities | environmental_health_safety_monitoring | onshore_electrical_maintenance | labor | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

OpEx#

Computes the total cost of all operating expenditures for the duration of the

simulation, including fixed costs. For further documentation, see the API docs here:

wombat.core.post_processor.Metrics.opex().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"by_categoryTrueshows the port fees, fixed costs, labor costs, equipment costs, and materials costs in addition the total OpExFalseshows only the total OpEx

Example Usage:

style(metrics.opex("annual"))

| OpEx | |

|---|---|

| year | |

| 2002 | 103,545,704.73 |

| 2003 | 108,245,841.55 |

| 2004 | 123,513,015.80 |

| 2005 | 112,745,662.04 |

| 2006 | 127,628,050.26 |

| 2007 | 119,685,564.71 |

| 2008 | 129,119,034.16 |

| 2009 | 131,514,587.10 |

| 2010 | 136,982,032.82 |

| 2011 | 114,560,440.33 |

| 2012 | 124,858,489.81 |

| 2013 | 113,242,049.65 |

| 2014 | 123,611,011.64 |

| 2015 | 119,463,728.78 |

| 2016 | 134,676,421.29 |

| 2017 | 138,628,982.87 |

| 2018 | 104,981,057.77 |

| 2019 | 112,416,090.03 |

| 2020 | 107,140,957.38 |

| 2021 | 128,473,953.86 |

style(metrics.opex("annual", by_category=True))

| operations | port_fees | equipment_cost | total_labor_cost | materials_cost | OpEx | |

|---|---|---|---|---|---|---|

| year | ||||||

| 2002 | 0.00 | 0.00 | 99,238,761.37 | 2,176,203.36 | 2,130,740 | 103,545,704.73 |

| 2003 | 0.00 | 0.00 | 103,436,787.16 | 2,198,354.39 | 2,610,700 | 108,245,841.55 |

| 2004 | 0.00 | 0.00 | 118,616,584.32 | 2,460,631.47 | 2,435,800 | 123,513,015.80 |

| 2005 | 0.00 | 0.00 | 107,633,090.98 | 2,379,791.06 | 2,732,780 | 112,745,662.04 |

| 2006 | 0.00 | 0.00 | 121,564,322.14 | 2,649,044.12 | 3,414,684 | 127,628,050.26 |

| 2007 | 0.00 | 0.00 | 114,880,287.47 | 2,439,237.23 | 2,366,040 | 119,685,564.71 |

| 2008 | 0.00 | 0.00 | 123,351,316.89 | 2,730,705.27 | 3,037,012 | 129,119,034.16 |

| 2009 | 0.00 | 0.00 | 125,564,178.33 | 2,755,068.77 | 3,195,340 | 131,514,587.10 |

| 2010 | 0.00 | 0.00 | 131,249,745.49 | 2,796,947.32 | 2,935,340 | 136,982,032.82 |

| 2011 | 0.00 | 0.00 | 109,984,315.44 | 2,428,360.89 | 2,147,764 | 114,560,440.33 |

| 2012 | 0.00 | 0.00 | 119,671,462.83 | 2,644,162.98 | 2,542,864 | 124,858,489.81 |

| 2013 | 0.00 | 0.00 | 108,426,698.98 | 2,380,898.68 | 2,434,452 | 113,242,049.65 |

| 2014 | 0.00 | 0.00 | 118,336,270.50 | 2,525,921.14 | 2,748,820 | 123,611,011.64 |

| 2015 | 0.00 | 0.00 | 115,058,999.97 | 2,406,828.81 | 1,997,900 | 119,463,728.78 |

| 2016 | 0.00 | 0.00 | 129,468,876.15 | 2,957,485.15 | 2,250,060 | 134,676,421.29 |

| 2017 | 0.00 | 0.00 | 131,773,721.13 | 2,954,749.74 | 3,900,512 | 138,628,982.87 |

| 2018 | 0.00 | 0.00 | 101,444,589.20 | 2,155,228.57 | 1,381,240 | 104,981,057.77 |

| 2019 | 0.00 | 0.00 | 107,891,457.24 | 2,310,780.79 | 2,213,852 | 112,416,090.03 |

| 2020 | 0.00 | 0.00 | 103,076,521.90 | 2,344,911.48 | 1,719,524 | 107,140,957.38 |

| 2021 | 0.00 | 0.00 | 122,118,493.37 | 2,699,760.49 | 3,655,700 | 128,473,953.86 |

Process Times#

Computes the total number of hours spent from repair request submission to completion,

performing repairs, and the number of request for each subassembly and repair category.

For further documentation, see the API docs here:

wombat.core.post_processor.Metrics.process_times().

Inputs:

include_incompletesTrue: include requests that have been submitted, but not completed.False: only include requests that have been completed.

Example Usage:

style(metrics.process_times())

| time_to_completion | process_time | downtime | time_to_start | N | ||

|---|---|---|---|---|---|---|

| subassembly | task | |||||

| anchor | anchor replacement | 17,856.22 | 8,758.06 | 8,755.67 | 9,230.48 | 19 |

| major anchor repair | 11,710.23 | 5,032.57 | 5,031.88 | 6,984.24 | 18 | |

| array cable | array cable major repair | 41,199.47 | 23,744.35 | 0.00 | 19,417.45 | 38 |

| array cable replacement | 47,411.93 | 29,724.17 | 0.00 | 18,528.17 | 34 | |

| ballast pump | minor ballast pump repair | 3,070.56 | 723.12 | 711.85 | 2,632.77 | 22 |

| drive_train | main shaft major repair | 537,258.28 | 5,052.33 | 5,046.19 | 532,935.27 | 39 |

| main shaft minor repair | 49,743.20 | 21,475.04 | 21,145.94 | 33,685.48 | 342 | |

| main shaft replacement | 10,478.33 | 4,439.61 | 4,437.31 | 6,140.54 | 8 | |

| electrical system | power electrical system major repair | 392,911.07 | 1,777.35 | 1,770.05 | 391,282.82 | 24 |

| power electrical system major replacement | 3,156.02 | 913.60 | 912.24 | 2,282.32 | 3 | |

| power electrical system minor repair | 74,452.01 | 30,620.52 | 30,151.93 | 53,159.26 | 545 | |

| export cable | export cable subsea inspection | 10,751.43 | 2,756.22 | 0.00 | 8,814.16 | 20 |

| generator | annual turbine inspection | 1,371,023.77 | 172,965.02 | 171,636.55 | 1,211,281.60 | 1,429 |

| direct drive generator major repair | 632,083.32 | 6,824.77 | 6,813.07 | 627,151.24 | 50 | |

| direct drive generator major replacement | 30,708.29 | 16,544.20 | 16,538.40 | 14,806.29 | 17 | |

| direct drive generator minor repair | 128,669.15 | 63,800.22 | 63,011.72 | 79,042.46 | 822 | |

| hydraulic pitch system | major pitch system repair | 65,164.92 | 52,185.95 | 52,021.65 | 18,319.19 | 242 |

| major pitch system replacement | 1,727.53 | 344.53 | 343.35 | 1,481.78 | 3 | |

| minor pitch system repair | 242,543.89 | 129,297.99 | 128,169.35 | 136,027.48 | 1,239 | |

| mooring lines | buoyancy module replacement | 11,645.63 | 9,170.24 | 9,140.46 | 3,313.24 | 39 |

| marine growth removal | 51,641.15 | 36,270.44 | 36,085.83 | 18,732.75 | 177 | |

| mooring line major repair | 20,254.11 | 8,118.07 | 8,116.39 | 12,330.60 | 24 | |

| mooring line replacement | 23,537.30 | 12,977.88 | 12,972.67 | 10,784.81 | 23 | |

| power converter | power converter major repair | 4,910,626.46 | 34,171.04 | 34,065.97 | 4,882,176.00 | 450 |

| power converter minor repair | 120,876.69 | 63,167.50 | 62,518.22 | 72,111.59 | 737 | |

| power converter replacement | 166,551.97 | 61,279.15 | 61,211.88 | 109,775.34 | 112 | |

| rotor_blades | blades major repair | 273,451.41 | 1,874.04 | 1,870.25 | 271,666.64 | 14 |

| blades major replacement | 3,418.72 | 3,200.33 | 3,199.95 | 219.03 | 1 | |

| blades minor repair | 130,228.29 | 71,453.27 | 70,941.02 | 69,132.07 | 691 | |

| supporting_structure | structural annual inspection | 1,615,890.58 | 153,557.95 | 152,224.33 | 1,468,225.34 | 1,440 |

| structural subsea inspection | 1,488,960.64 | 22,876.13 | 22,307.16 | 1,473,017.51 | 720 | |

| transformer | oss annual inspection | 12,438.79 | 6,974.04 | 6,937.53 | 6,240.90 | 38 |

| oss minor repair | 1,763.41 | 408.00 | 404.49 | 1,415.87 | 7 | |

| yaw_system | yaw system major repair | 17,900.28 | 564.43 | 564.11 | 17,433.28 | 4 |

| yaw system major replacement | 872.95 | 574.11 | 574.00 | 299.20 | 1 | |

| yaw system minor repair | 34,263.31 | 15,667.87 | 15,471.79 | 23,700.89 | 231 |

style(metrics.process_times(include_incompletes=False))

| time_to_completion | process_time | downtime | time_to_start | N | ||

|---|---|---|---|---|---|---|

| subassembly | task | |||||

| anchor | anchor replacement | 17,856.22 | 8,758.06 | 8,755.67 | 9,230.48 | 17 |

| major anchor repair | 11,710.23 | 5,032.57 | 5,031.88 | 6,984.24 | 14 | |

| array cable | array cable major repair | 41,199.47 | 23,744.35 | 0.00 | 19,417.45 | 34 |

| array cable replacement | 47,411.93 | 29,724.17 | 0.00 | 18,528.17 | 29 | |

| ballast pump | minor ballast pump repair | 3,070.56 | 723.12 | 711.85 | 2,632.77 | 22 |

| drive_train | main shaft major repair | 537,258.28 | 5,052.33 | 5,046.19 | 532,935.27 | 25 |

| main shaft minor repair | 49,743.20 | 21,475.04 | 21,145.94 | 33,685.48 | 342 | |

| main shaft replacement | 10,478.33 | 4,439.61 | 4,437.31 | 6,140.54 | 8 | |

| electrical system | power electrical system major repair | 392,911.07 | 1,777.35 | 1,770.05 | 391,282.82 | 19 |

| power electrical system major replacement | 3,156.02 | 913.60 | 912.24 | 2,282.32 | 3 | |

| power electrical system minor repair | 74,452.01 | 30,620.52 | 30,151.93 | 53,159.26 | 545 | |

| export cable | export cable subsea inspection | 10,633.43 | 2,718.15 | 0.00 | 8,814.16 | 19 |

| generator | annual turbine inspection | 1,371,023.77 | 172,965.02 | 171,636.55 | 1,211,281.60 | 1,429 |

| direct drive generator major repair | 632,083.32 | 6,824.77 | 6,813.07 | 627,151.24 | 31 | |

| direct drive generator major replacement | 30,708.29 | 16,544.20 | 16,538.40 | 14,806.29 | 17 | |

| direct drive generator minor repair | 128,669.15 | 63,800.22 | 63,011.72 | 79,042.46 | 821 | |

| hydraulic pitch system | major pitch system repair | 65,164.92 | 52,185.95 | 52,021.65 | 18,319.19 | 242 |

| major pitch system replacement | 1,727.53 | 344.53 | 343.35 | 1,481.78 | 3 | |

| minor pitch system repair | 242,543.89 | 129,297.99 | 128,169.35 | 136,027.48 | 1,239 | |

| mooring lines | buoyancy module replacement | 11,645.63 | 9,170.24 | 9,140.46 | 3,313.24 | 39 |

| marine growth removal | 51,481.41 | 36,126.44 | 35,950.64 | 18,634.96 | 176 | |

| mooring line major repair | 20,254.11 | 8,118.07 | 8,116.39 | 12,330.60 | 22 | |

| mooring line replacement | 23,537.30 | 12,977.88 | 12,972.67 | 10,784.81 | 21 | |

| power converter | power converter major repair | 4,910,626.46 | 34,171.04 | 34,065.97 | 4,882,176.00 | 276 |

| power converter minor repair | 120,876.69 | 63,167.50 | 62,518.22 | 72,111.59 | 737 | |

| power converter replacement | 165,200.08 | 60,948.62 | 60,913.35 | 108,716.19 | 110 | |

| rotor_blades | blades major repair | 273,451.41 | 1,874.04 | 1,870.25 | 271,666.64 | 12 |

| blades major replacement | 3,418.72 | 3,200.33 | 3,199.95 | 219.03 | 1 | |

| blades minor repair | 130,228.29 | 71,453.27 | 70,941.02 | 69,132.07 | 691 | |

| supporting_structure | structural annual inspection | 1,615,890.58 | 153,557.95 | 152,224.33 | 1,468,225.34 | 1,440 |

| structural subsea inspection | 1,488,960.64 | 22,876.13 | 22,307.16 | 1,473,017.51 | 574 | |

| transformer | oss annual inspection | 12,438.79 | 6,974.04 | 6,937.53 | 6,240.90 | 38 |

| oss minor repair | 1,763.41 | 408.00 | 404.49 | 1,415.87 | 7 | |

| yaw_system | yaw system major repair | 17,900.28 | 564.43 | 564.11 | 17,433.28 | 2 |

| yaw system major replacement | 872.95 | 574.11 | 574.00 | 299.20 | 1 | |

| yaw system minor repair | 34,263.31 | 15,667.87 | 15,471.79 | 23,700.89 | 231 |

Request Summary#

Computes the total number of submitted, canceled, incomplete, and completed repair and

maintenance request by subassembly and task description. For further documentation, see

the API docs here: wombat.core.post_processor.Metrics.request_summary().

Example Usage:

style(metrics.request_summary())

| total_requests | canceled_requests | incomplete_requests | completed_requests | ||

|---|---|---|---|---|---|

| subassembly | task | ||||

| anchor | anchor replacement | 19 | 0 | 2 | 17 |

| major anchor repair | 18 | 0 | 4 | 14 | |

| array cable | array cable major repair | 38 | 0 | 4 | 34 |

| array cable replacement | 34 | 0 | 5 | 29 | |

| ballast pump | minor ballast pump repair | 22 | 0 | 0 | 22 |

| drive_train | main shaft major repair | 39 | 0 | 14 | 25 |

| main shaft minor repair | 342 | 0 | 0 | 342 | |

| main shaft replacement | 8 | 0 | 0 | 8 | |

| electrical system | power electrical system major repair | 24 | 0 | 5 | 19 |

| power electrical system major replacement | 3 | 0 | 0 | 3 | |

| power electrical system minor repair | 545 | 0 | 0 | 545 | |

| export cable | export cable subsea inspection | 20 | 0 | 1 | 19 |

| generator | annual turbine inspection | 1,432 | 3 | 0 | 1,429 |

| direct drive generator major repair | 52 | 2 | 19 | 31 | |

| direct drive generator major replacement | 17 | 0 | 0 | 17 | |

| direct drive generator minor repair | 822 | 0 | 1 | 821 | |

| hydraulic pitch system | major pitch system repair | 242 | 0 | 0 | 242 |

| major pitch system replacement | 3 | 0 | 0 | 3 | |

| minor pitch system repair | 1,239 | 0 | 0 | 1,239 | |

| mooring lines | buoyancy module replacement | 40 | 1 | 0 | 39 |

| marine growth removal | 177 | 0 | 1 | 176 | |

| mooring line major repair | 25 | 1 | 2 | 22 | |

| mooring line replacement | 23 | 0 | 2 | 21 | |

| power converter | power converter major repair | 533 | 83 | 174 | 276 |

| power converter minor repair | 740 | 3 | 0 | 737 | |

| power converter replacement | 113 | 1 | 2 | 110 | |

| rotor_blades | blades major repair | 14 | 0 | 2 | 12 |

| blades major replacement | 1 | 0 | 0 | 1 | |

| blades minor repair | 691 | 0 | 0 | 691 | |

| supporting_structure | structural annual inspection | 1,440 | 0 | 0 | 1,440 |

| structural subsea inspection | 720 | 0 | 146 | 574 | |

| transformer | oss annual inspection | 38 | 0 | 0 | 38 |

| oss minor repair | 7 | 0 | 0 | 7 | |

| yaw_system | yaw system major repair | 4 | 0 | 2 | 2 |

| yaw system major replacement | 1 | 0 | 0 | 1 | |

| yaw system minor repair | 231 | 0 | 0 | 231 |

Power Production#

Computes the total power production for the wind farm. For further documentation, see

the API docs here: wombat.core.post_processor.Metrics.power_production().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"by, as explained above options: "windfarm" and "turbine"units"kwh": kilowatt-hours (kWh)

"mwh": megawatt-hours (MWh)

"gwh": gigawatt-hours (GWh)

Example Usage:

# Project totals, in kWh, at the wind farm level

style(metrics.power_production(frequency="project", by="windfarm", units="kwh"))

| windfarm | |

|---|---|

| Project Energy Production (kWh) | 106,399,355,837.00 |

# Project totals, in MWh, at the wind farm level

style(metrics.power_production(frequency="project", units="mwh"))

| windfarm | |

|---|---|

| Project Energy Production (MWh) | 106,399,355.84 |

# Project totals, in GWh, at the wind farm level

style(metrics.power_production(frequency="project"))

| windfarm | |

|---|---|

| Project Energy Production (GWh) | 106,399.36 |

Hydrogen Production#

Computes the total hydrogen production for the electrolyzer(s). For further documentation, see

the API docs here: wombat.core.post_processor.Metrics.h2_production().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"by: Similar to the common definition, but with electrolyzer specific inputs."total": total H2 produced for all electrolyzers

"electrolyzer": H2 production for all and each electrolyzer

units"kgph": kilograms per hour (kgph)

"tph": metric tonnes hours (tph)

Example Usage:

Please note, this will raise an error since this analysis does not feature a modeled electrolyzer.

# Project totals, in kWh, at the wind farm level

style(metrics.h2_production(frequency="project", by="total", units="kgph"))

---------------------------------------------------------------------------

ValueError Traceback (most recent call last)

Cell In[38], line 2

1 # Project totals, in kWh, at the wind farm level

----> 2 style(metrics.h2_production(frequency="project", by="total", units="kgph"))

File /opt/hostedtoolcache/Python/3.13.11/x64/lib/python3.13/site-packages/wombat/core/post_processor.py:2328, in Metrics.h2_production(self, frequency, by, units)

2292 """Calculates the hydrogen production for the simulation at a project, annual,

2293 or monthly level that can be broken out by electrolyzer.

2294

(...) 2325 If :py:attr:`units` is not one of "kg" or "tn".

2326 """

2327 if self.electrolyzer_rated_production.size == 0:

-> 2328 raise ValueError("No electrolyzers available to analyze.")

2329 frequency = _check_frequency(frequency, which="all")

2331 by = by.lower().strip()

ValueError: No electrolyzers available to analyze.

Net Present Value#

Calculates the net present value (NPV) for the project, as \(NPV = (Power * OfftakePrice - OpEx) / (1 + DiscountRate)\).

For further documentation, see the API docs here: wombat.core.post_processor.Metrics.npv().

Inputs:

frequency, as explained above, options: "project", "annual", "monthly", and "month-year"discount_rate: The rate of return that could be earned on alternative investments, by default 0.025.offtake_price: Price of energy, per MWh, by default 80.

style(metrics.opex("annual"))

| OpEx | |

|---|---|

| year | |

| 2002 | 103,545,704.73 |

| 2003 | 108,245,841.55 |

| 2004 | 123,513,015.80 |

| 2005 | 112,745,662.04 |

| 2006 | 127,628,050.26 |

| 2007 | 119,685,564.71 |

| 2008 | 129,119,034.16 |

| 2009 | 131,514,587.10 |

| 2010 | 136,982,032.82 |

| 2011 | 114,560,440.33 |

| 2012 | 124,858,489.81 |

| 2013 | 113,242,049.65 |

| 2014 | 123,611,011.64 |

| 2015 | 119,463,728.78 |

| 2016 | 134,676,421.29 |

| 2017 | 138,628,982.87 |

| 2018 | 104,981,057.77 |

| 2019 | 112,416,090.03 |

| 2020 | 107,140,957.38 |

| 2021 | 128,473,953.86 |